Top Benefits of Using Zirconia Ceramic Foam Filters in Manufacturing

May. 21, 2025

In modern industrial manufacturing, filtration efficiency and material integrity play critical roles in determining product quality and operational cost. One of the most advanced and trusted solutions for high-temperature filtration is the zirconia ceramic foam filter. Engineered to perform under extreme conditions, these filters offer manufacturers across industries—from foundries to aerospace—unparalleled advantages in casting and metallurgical processes.

What Are Zirconia Ceramic Foam Filters?

Zirconia ceramic foam filters are high-porosity ceramic structures made from zirconium dioxide (ZrO₂). These filters are known for their thermal stability, high melting point (~2700°C), and superior chemical inertness. Designed to remove non-metallic inclusions and entrapped gas from molten metals, zirconia ceramic foam filters ensure smooth metal flow, defect-free castings, and enhanced surface finish in end products.

Superior Thermal Resistance for Extreme Applications

Zirconia ceramic foam filters excel in high-temperature environments, making them the ideal solution for filtering molten steel and superalloys. Unlike other materials, zirconia maintains its mechanical strength and dimensional stability even when subjected to thermal shocks or prolonged exposure to extreme heat.

Melting point exceeding 2700°C

Resistant to slag, molten metal corrosion, and chemical wear

Ideal for stainless steel, nickel-based alloys, and titanium alloys

By using these filters, manufacturers can significantly reduce equipment wear and failure rates, especially in high-throughput operations.

Exceptional Filtration Efficiency

The porous structure of zirconia ceramic foam filters provides deep filtration, effectively capturing non-metallic inclusions, oxides, and slag particles from molten metal. This leads to a substantial improvement in the mechanical properties of castings, including:

Higher tensile strength

Improved elongation

Reduced porosity and shrinkage cavities

The uniform pore size ensures that even microscopic impurities are trapped, resulting in high-quality, defect-free components that meet stringent industry standards.

Improved Flow Dynamics of Molten Metal

Zirconia ceramic foam filters are engineered to facilitate laminar flow, reducing turbulence during casting. Turbulent metal flow often introduces air entrapment and splashing, leading to internal defects and inconsistent fill rates.

With zirconia filters:

Molten metal flows evenly and smoothly

Reduced velocity variations in molds

Minimized oxidation and inclusions

This characteristic is crucial for producing critical components in aerospace, automotive, and defense applications where dimensional accuracy and integrity are non-negotiable.

Compatibility with a Wide Range of Alloys

Zirconia filters offer broad compatibility with various alloys, including:

Carbon steel and stainless steel

Inconel, Monel, and other nickel-based alloys

Titanium and cobalt alloys

This versatility makes them the go-to solution for manufacturers working across different sectors. Whether you’re casting turbine blades or engine components, zirconia ceramic foam filters deliver consistent performance.

Reduced Scrap Rate and Enhanced Yield

By eliminating common casting defects, zirconia ceramic foam filters contribute directly to reducing scrap and rework. Every defective component incurs additional cost in labor, energy, and materials. Using zirconia filters enables:

Higher first-pass yield

Lower rejection rates

Significant reduction in downstream processing costs

In mass production, even a 2-3% improvement in yield can translate into substantial financial savings, boosting the overall efficiency of the manufacturing line.

Extended Service Life and Durability

Compared to other ceramic foam filters, zirconia-based filters offer greater resistance to thermal cycling, chemical degradation, and physical wear. They can withstand multiple pouring cycles in some applications, depending on operating conditions.

Key durability benefits include:

Low thermal expansion

High fracture toughness

Minimal filter degradation over time

This leads to less frequent replacements, reducing downtime and maintenance costs, which is essential for manufacturers focusing on lean operations and continuous productivity.

Eco-Friendly and Sustainable Manufacturing

Adopting zirconia ceramic foam filters aligns with sustainable manufacturing goals by:

Reducing waste output due to fewer defects

Minimizing energy use via efficient melting and casting

Decreasing emissions from fewer re-melts and reprocessing

As environmental regulations tighten worldwide, zirconia filters offer a green solution without compromising on performance, helping industries meet compliance standards and improve their corporate environmental footprint.

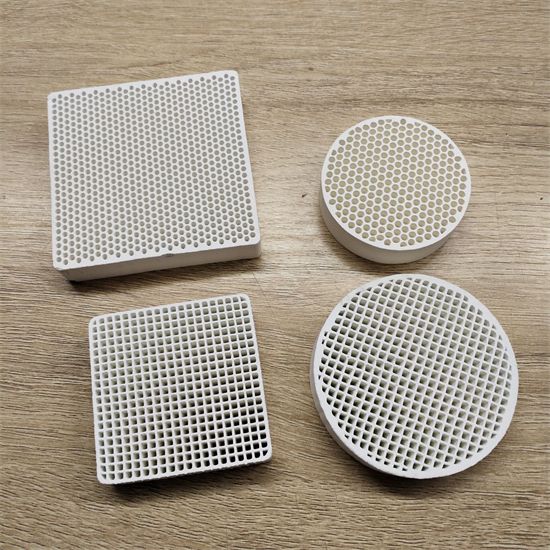

Customizable Designs for Specific Needs

Manufacturers can source zirconia ceramic foam filters in a wide range of:

Pore sizes (PPI – pores per inch)

Geometries and thicknesses

Filter grades and coating materials

This level of customization enables precise control over filtration performance and allows adaptation to specific mold designs, metal flow rates, and casting complexities.

Applications Across Diverse Industries

The effectiveness of zirconia ceramic foam filters has led to their widespread adoption in:

Automotive: Engine blocks, cylinder heads, pistons

Aerospace: Turbine blades, structural components

Energy: Nuclear fuel housings, power plant parts

Medical: Surgical implants, orthopedic components

Defense: Armor plates, missile and jet components

In each of these sectors, product integrity and reliability are mission-critical, and zirconia ceramic foam filters deliver on both fronts.

Final Thoughts

Zirconia ceramic foam filters are no longer just an option—they are a strategic investment for manufacturers aiming to produce high-integrity, high-performance metal castings. Their benefits are measurable, repeatable, and crucial in gaining a competitive edge in today's precision-focused manufacturing world.

From reducing casting defects to enabling cleaner, smoother metal flows, these filters have transformed how we approach quality control in metallurgical applications.

116

0

0

Previous: None

Next: None

Comments

All Comments (0)